Solar power is an excellent alternative energy source, and investing in solar panels is a smart move towards a more sustainable future. If you’re considering harnessing the power of the sun, you may have come across the Industrial 500 Watt Solar Panel Suppliers Price 535-560W. In this beginner’s guide, we’ll walk you through the step-by-step process of using these solar panels effectively and efficiently.

Step 1: Assess Your Energy Needs

Before purchasing solar panels, it’s crucial to evaluate your energy requirements. Consider the appliances and electronics you use regularly and calculate your daily energy consumption. This assessment will determine the number of solar panels you’ll need to meet your energy goals.

Step 2: Research and Compare Suppliers

To ensure you’re getting the best quality solar panels at a competitive price, research and compare different suppliers. Look for reputable suppliers offering Industrial 500 Watt Solar Panel Suppliers Price 535-560W and read reviews from other customers to gauge their reliability and customer satisfaction.

Step 3: Determine Panel Placement

The placement of your solar panels will directly impact their efficiency. Choose a location where panels receive ample sunlight throughout the day, ideally with minimal shading. South-facing rooftops are often the best option, but ground-mounted installations can also work well if you have the space. Consider any local regulations or homeowner association rules before finalizing the panel placement.

Step 4: Install and Connect Solar Panels

If you’re confident in your DIY skills, installing the solar panels yourself can save you money. However, it’s essential to follow all safety guidelines and instructions provided by the supplier. Ensure that the panels are securely mounted and properly connected to your home’s electrical system.

Step 5: Monitor and Maintain

After the installation, regularly monitor the performance of your solar panels. Keep an eye on their energy production, and if you notice any significant drops, check for possible obstructions or damage. Additionally, schedule periodic inspections and maintenance to ensure your panels remain clean and functioning optimally.

Step 6: Benefit from Solar Power

With your Industrial 500 Watt Solar Panel Suppliers Price 535-560W in place, you can start enjoying the benefits of solar power. Track your energy savings, reduce your carbon footprint, and take pride in being part of the clean energy movement.

Conclusion

Switching to solar power may seem overwhelming at first, but with the right information and guidance, it becomes much simpler. By following this step-by-step guide, you can confidently use Industrial 500 Watt Solar Panel Suppliers Price 535-560W and contribute to a greener and more sustainable future. Embrace the power of solar energy and take control of your electricity consumption.

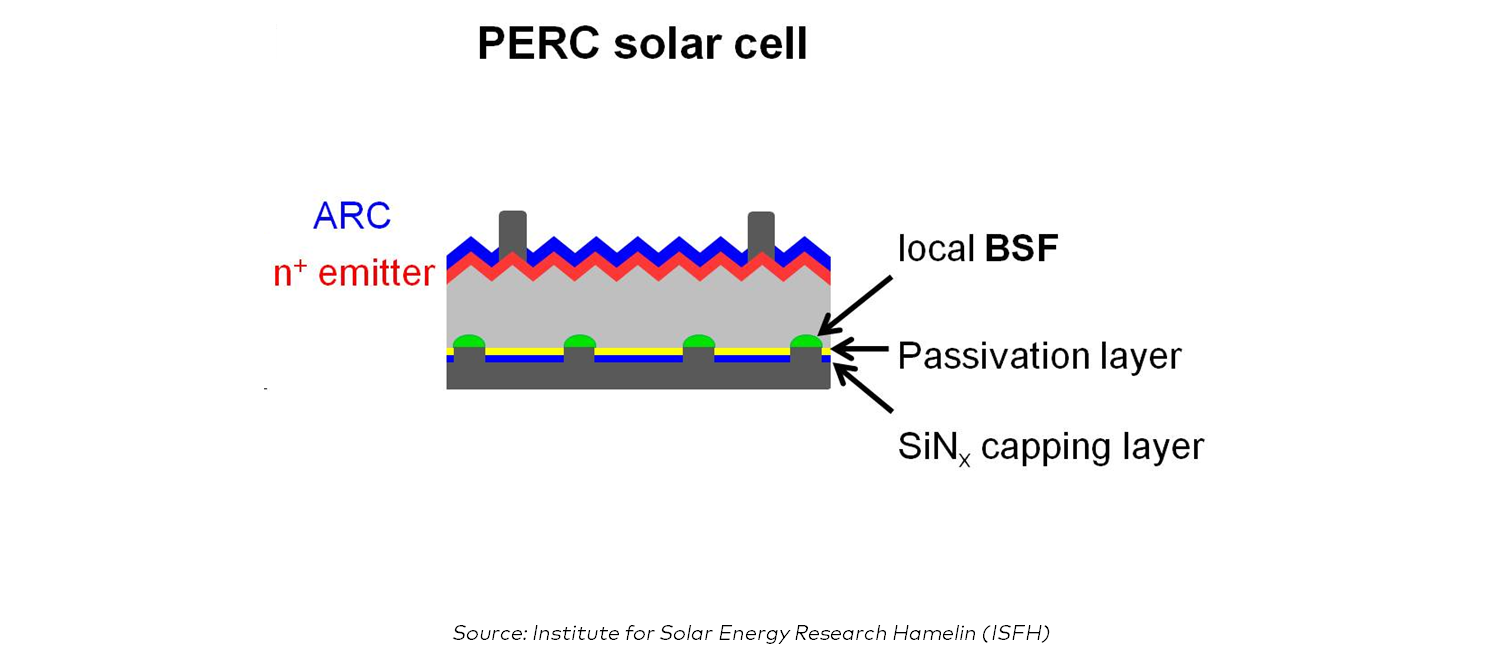

1. What does PERC mean?

1. What does PERC mean?