In the field of security, stable power supply is the cornerstone of system operation. Lead-acid batteries, known for their reliability and cost-effectiveness, are an indispensable power solution for alarm security systems. This article will systematically introduce the role, technical selection, installation, maintenance, and monitoring management of lead-acid batteries in security systems.

The Key Role of

Lead-acid batteries play several critical roles in security systems:

1. Backup Power Supply

During power outages or instability, lead-acid batteries provide temporary power, ensuring the continuous operation of key equipment like surveillance cameras and alarm systems, reducing security risks.

2. Emergency Lighting Support

In emergencies such as fires or natural disasters, lead-acid batteries power emergency lighting systems, ensuring safe evacuation.

3. System Stability Protection

Lead-acid batteries provide stable power, preventing voltage fluctuations from damaging electronic equipment in the security system.

4. Data Security Protection

During power outages, lead-acid batteries supply power to data storage devices, preventing data loss.

Technical Selection and Configuration

Choosing the right lead-acid battery is crucial for the performance of security systems:

1. Battery Model Selection

Choose 12V, 24V, or 48V lead-acid batteries based on the scale and needs of the security system.

2. Capacity and Discharge Rate

Ensure the battery capacity meets backup time requirements and the discharge rate matches the system load.

3. Service Life and Maintenance

Select low-maintenance or maintenance-free lead-acid batteries to reduce long-term operational costs. Kaiying Power's lead-acid batteries are known for their high efficiency and long life, making them an ideal choice for security systems.

Charging Management and Maintenance

Proper charging management is essential to extend battery life and ensure system stability:

1. Smart Charging

Use smart chargers to automatically adjust charging parameters, preventing overcharging and undercharging.

2. Equalization Charging

Perform regular equalization charging to maintain overall battery performance.

3. Temperature Compensation

Adjust charging voltage according to ambient temperature changes to ensure safe battery operation.

Installation and Wiring

Correct installation and wiring are prerequisites for ensuring battery performance and safety:

1. Installation Environment

Ensure batteries are installed in a clean, dry, and well-ventilated environment.

2. Safe Wiring

Follow electrical safety standards for wiring, using appropriate terminals and insulation materials.

Monitoring and Warning

Real-time monitoring and warning systems can detect battery issues early, preventing potential risks:

1. Real-Time Monitoring

Use battery monitoring systems to track key parameters such as voltage, current, and temperature.

2. Warning System

Set warning thresholds to alert when battery parameters are abnormal.

Replacement Cycle

Regular performance testing and preventive replacement strategies ensure batteries remain in optimal condition:

1. Performance Testing

Conduct regular battery performance tests to assess battery health.

2. Preventive Replacement

Replace batteries before performance declines to avoid unexpected interruptions.

Lead-acid batteries play a crucial role in security systems, from backup power to data protection, ensuring stable system operation. By choosing the right batteries, managing charging smartly, monitoring accurately, and replacing timely, you can maximize battery performance and lifespan, ensuring the reliability and safety of your security system. Despite the emergence of new battery technologies, lead-acid batteries, with their mature and stable characteristics, will continue to play an important role in the security field for the foreseeable future. Kaiying Power is dedicated to providing high-quality lead-acid batteries to ensure your security system is always in top condition. Regarding battery for security system, battery for alarm system, please visit: www.kaiyingpower.com.

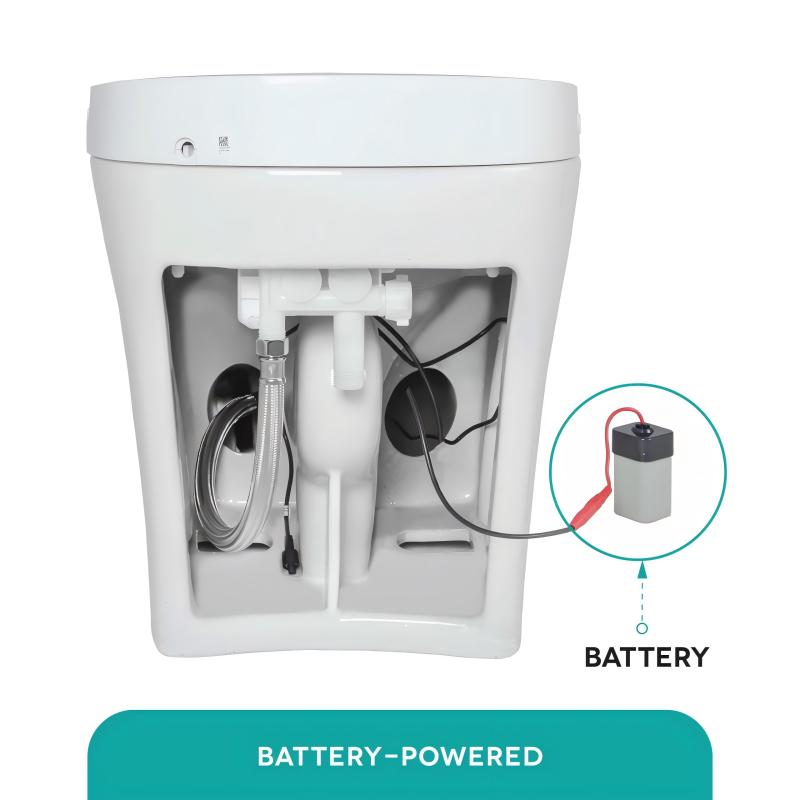

Battery Compatibility: Meeting the Electrical Needs of Smart Toilets

Battery Compatibility: Meeting the Electrical Needs of Smart Toilets Installation and Maintenance: Ensuring Stable Battery Operation

Installation and Maintenance: Ensuring Stable Battery Operation Safety and Charging: Protecting the Battery and Users

Safety and Charging: Protecting the Battery and Users Fault Detection and Warranty: Extending Battery Life

Fault Detection and Warranty: Extending Battery Life Environmental Disposal: Responsible Battery Recycling

Environmental Disposal: Responsible Battery Recycling

Understanding Maintenance-Free Lead-Acid Batteries

Understanding Maintenance-Free Lead-Acid Batteries

Technical Maintenance and Professional Support

Technical Maintenance and Professional Support